What Makes Nbcbdz BK Control Transformer Factory Worth Considering

When it comes to ensuring stable and secure operation in industrial settings, BK Control Transformer Factory products play a key role in protecting electrical systems. These transformers are designed to supply steady voltage to control circuits, preventing fluctuations that could cause malfunctions or damage to sensitive components. Their purpose extends beyond power conversion—they act as safeguards that maintain operational integrity in environments where reliability is essential.

In industrial automation, voltage instability can interrupt production and increase maintenance costs. Control transformers are engineered to regulate current levels, reducing surges that may result from load variations or power inconsistencies. By managing this flow, equipment functions more smoothly, maintaining precision and reducing the likelihood of electrical interference or shutdowns.

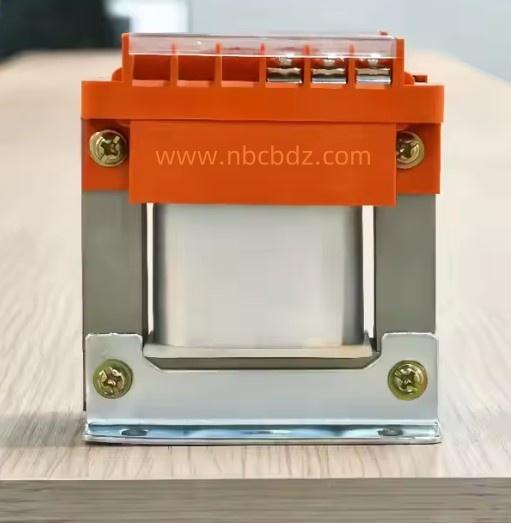

Construction quality is fundamental to a control transformer's effectiveness. High-grade materials and precise coil arrangements ensure consistent magnetic balance and thermal stability. This minimizes overheating and extends product lifespan even under demanding working conditions. Manufacturers that focus on insulation design and mechanical strength create transformers capable of performing efficiently over extended cycles.

One major advantage of these transformers is their ability to isolate control circuits from main power sources. This electrical separation prevents unexpected voltage spikes from reaching sensitive equipment, improving both safety and energy stability. Isolation also supports better signal clarity, which is crucial for automated machinery that depends on precise command responses.

Another factor that defines a reliable control transformer is its testing and compliance with industry standards. Every unit should undergo voltage, temperature, and durability testing to ensure dependable performance. Nbcbdz integrates strict inspection protocols in its production process to align each transformer with modern industrial expectations. This approach ensures consistent operation while maintaining the safety of complex electrical systems.

Maintenance and usability also play a vital part in long-term efficiency. Transformers that feature accessible terminal connections and clear labeling simplify installation and routine inspection. When design focuses on practicality, it reduces downtime, allowing engineers to service or replace units without disrupting production.

From a broader perspective, reliable transformers contribute to operational efficiency across entire facilities. They help stabilize control power for automation lines, lighting systems, and monitoring panels. Consistent voltage supply also reduces wear on switches, relays, and control devices, allowing machinery to function more effectively with less strain on electrical components.

Modern industries are increasingly focusing on energy responsibility, and control transformers support this shift by optimizing power distribution and minimizing unnecessary loss. This contributes to smoother operations while reducing the environmental impact associated with unstable power use.

In conclusion, choosing a well-constructed control transformer is crucial for protecting industrial systems and improving reliability. A transformer built with attention to material quality, insulation, and testing provides stability that supports safe operation and efficient production. For durable and performance-oriented solutions designed for industrial applications, visit https://www.nbcbdz.com/product/

- Memes & Cultura da Comunidade

- Artigos e Análises

- Pessoal

- Oportunidade

- Projeto

- Conhecimento

- Dúvidas & Pedidos de Ajuda

- Reflexões & Opiniões

- Tendências

- Oyunlar

- Lançamentos & Anúncios

- Saúde & Bem Estar

- Eventos & Convites

- Conteúdo Técnico

- Entretenimento

- Networking

- Festas & Festivais

- Religião

- Iniciativas de Impacto